Copper Alloy Cage – An Ideal Choice for Efficient Aquaculture

Copper alloy cage

The cooper alloy cage is the best choice for efficient aquaculture. The copper alloy cage has many features: high efficiency, low-carbon and corrosion resistant performance, etc. There are almost no microorganisms attached to the copper mesh throughout the lifetime copper alloy cage, creating a healthier growing environment for fish.

The fishery and aquaculture industry are still important sources of food, nutrition, income and livelihood for hundreds of millions of people around the world. The world's per capita supply of aquatic products reached a record high of 20 kilograms in 2014 due to the rapid growth of aquaculture and the improvement of fisheries management. The aquaculture products have accounted for half of the total amount of aquatic products consumed by humans. How to use copper alloy cage for efficient aquaculture?

The copper alloy cage technology was born in 1975 with a history of over 40 years. The technology has got considerable development. The technology takes advantage of copper's natural antibacterial properties and corrosion resistance to avoid the growth of marine biological attachments in aquaculture nets and create cleaner and healthier conditions for fish aquaculture. At the same time, the technology reduces greatly the frequency of cleaning and replacing fishing nets or mariculturists management of fish. The technology also reduces the loss caused by predators attack and fish escape. At present, thousands of copper alloy cages have been put into use in Japan, Australia, Chile, Russia, America, Norway, Iceland, Greenland and other countries. There are many suitable for fish raised in copper alloy cage: rainbow trout, haddock, cod, halibut, large yellow croaker, bass, tiger puffer, yellowtail, salmon, cobia and other high economically valuable fish.

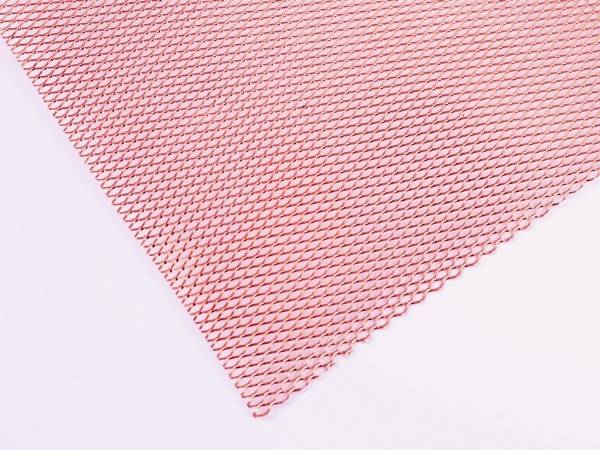

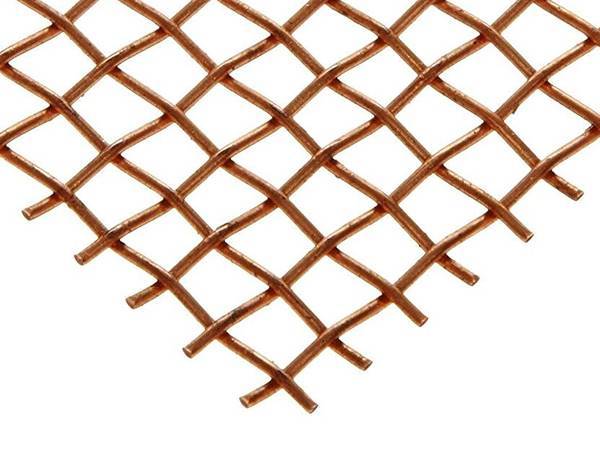

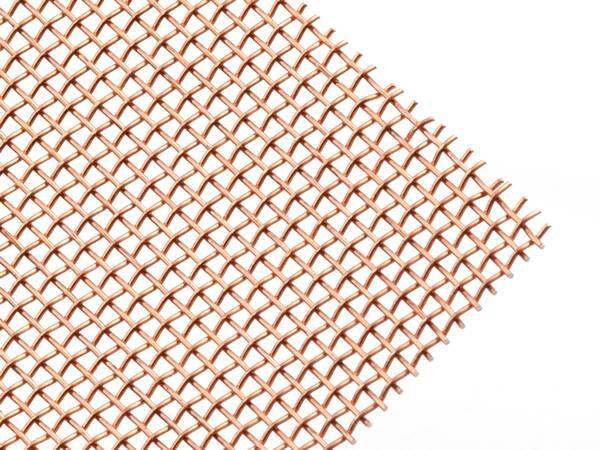

We specialize in the production of high-quality copper alloy cage. We adopt advanced German technology and strictly smelt materials. We specialize in the production of high-quality copper alloy aquaculture nets. We mainly produce copper alloy chain link mesh. We also provide copper alloy expanded mesh, copper alloy welded mesh, copper alloy perforated metal, copper alloy hexagonal mesh and copper alloy crimped woven mesh to meet the needs of the different kinds of fish.

What are special advantages of the copper alloy cage?

- Without Attachments, High Efficiency, Low-Carbon, Healthy and Eco-Friendly

The copper releases cupric ions very slowly when copper is immersed in seawater. Slight toxicity inhibits algal growth and greatly reduces attachments on the cage. There are almost no microorganisms attached to the copper mesh throughout its lifetime, creating a healthier growing environment for fish.

- The study data about the fish growth of South Korea's Gyeongsang University reveals that the growth rate of the fish in the copper alloy cage can be increased by 30% under the same conditions. There is no copper residue in the fish and fish skin. Lots of studies show copper ions released from solid copper alloy have no effect on organisms on the aquaculture. Copper concentration will not be higher than natural concentration without copper. It also will not accumulate in the food chain. Consumers can be at ease use.

- In the absence of microbial attachments, the frequency of manual cleaning and replacing of copper cages is reduced and the manpower, material and financial resources are saved. The synthetic fiber cage needs to be cleaned every half month. However, the copper cage only needs to be cleaned once or twice every two years.

- In the absence of microbial attachment and the breeding ground of bacteria, the disease of fish is effectively controlled. Therefore, it is wise to eliminate the use of antibiotics and chemicals in the cultivation process. It can provide healthier products for people.

- The water flow in the cage is impacted owing to lots of attachments. The activity space of aquatic products is reduced. So the attachments decline the survival rate and growth rate of fish and reduce the amino acid contained in the aquaculture seafood, and thus affect the nutrition and taste of the aquatic products.

- The technology of deep-sea cage aquaculture can alleviate the environmental pressure of offshore and harbor, expand the intensive farming and promote the healthy development of aquaculture.

The comparison diagram between the nylon aquaculture fish cage and copper alloy fish cage

- High Strength, High Hardness and Corrosion Resistant Performance

The copper alloy net is composed of 64 percent copper and 35.1 percent zinc. It adds 0.6 percent tin and 0.3 percent nickel to improve strength, hardness and corrosion resistant performance.

- The tensile strength of copper-zinc alloy can reach 600–800 N/mm2. Anti-wave resistant performance reaches grade 14 typhoons and grade 7 waves, and the flow resistance reaches 1.96 knots. Recently, Typhoon Mangkhut made landfall from the northern Philippines and landed in Haiyan town of Taishan, Guangdong at 17:00 on 16th. The maximum wind power is grade 14 near center and the minimum central pressure is 955 hPa when typhoon landed. Boegger copper-zinc alloy cage, which is used in the south China sea, is almost intact. The mariculturists barely suffered economic damage. However, mariculturists which used other cages, have suffered substantial economic losses. The traditional small cages in Fujian province is destroyed and the direct economic losses stood at RMB 1.18 billion.

- High-strength copper-zinc alloy net reduces the attack of predators but doesn't hurt predators, and greatly reduces the chances of farmed fish escaping into the natural environment.

- The copper has corrosion resistant performance in aqueous solutions of fresh water, seawater, or neutral salts. Due to the action of the oxide film, copper presents blunt states of Cu2 O and CuO. Meanwhile, adding tin and nickel to Boegger copper alloy net is more likely to guarantee corrosion resistance performance.

- Long life time and 100% Recycle

The service life of copper alloy net is about 10 years. Since copper is a non-renewable resource, it can be 100% recycled with the high market price after the end of the breeding cycle. However, the average service life of the traditional cage system is two to three years, and after the breeding cycle, it can only be treated as wastes.

From the above descriptions, it is easy to see that the the copper alloy aquaculture cage is superior to the traditional aquaculture cage. If you are interested in this new technology and new products, just feel free to contact us. We are looking forward to your contact.

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

![Knitted Copper Mesh]()

![Woven Copper Mesh]()

![Blackened copper wire mesh image]()

![A roll of brass wire mesh with golden yellow color.]()

![Phosphor copper mesh image]()

![Expanded Copper Mesh]()

![Micro expanded copper mesh]()

![Crimped Copper Wire Mesh]()

![Coarse Copper Mesh]()

![Medium Copper Mesh]()

![Fine Copper Mesh]()

![Copper Shielding Mesh]()

![Cable Shielding Mesh]()

![Faraday Cage]()

![Copper Alloy Fish Cage]()

![Copper Scrubber]()

![Stuf-Fit Copper Mesh]()

![Copper Insect Screen]()

![Copper Fireplace Screen]()

![A piece of copper mesh mask on the gray background.]()

![Fused Glass on Copper Mesh]()

![Copper Mesh Artworks]()