Micro Expanded Copper Mesh Aircraft Lightning Defence Application

For the past 70 years, the primary material for aircraft structures has been aluminum. As aircraft performance has improved, carbon fiber composites are increasingly being used as the primary material for structures. But composites are poor conductors of electric current and without proper protection they are susceptible to severe damage in a lightning strike. Micro expanded copper mesh is applied to the surface of these composite structures, and the lightning strike energy is dissipated on the component surface, thus preventing damage to the composite material below and compromising the safety of the aircraft.

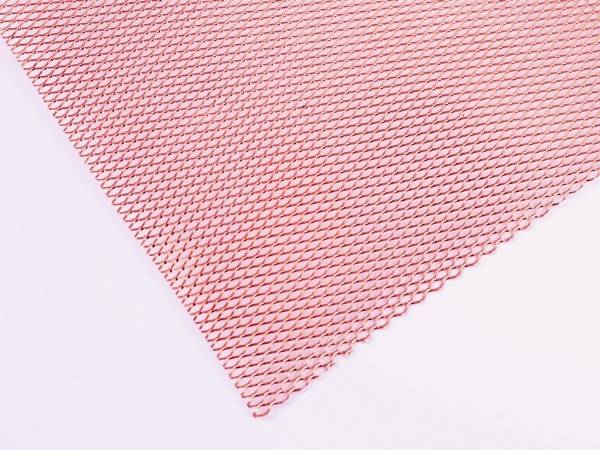

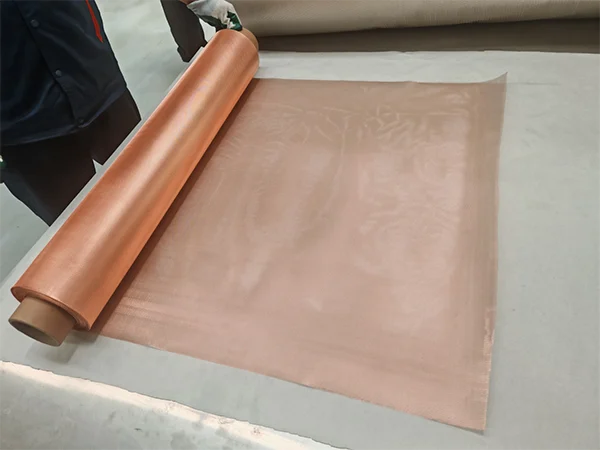

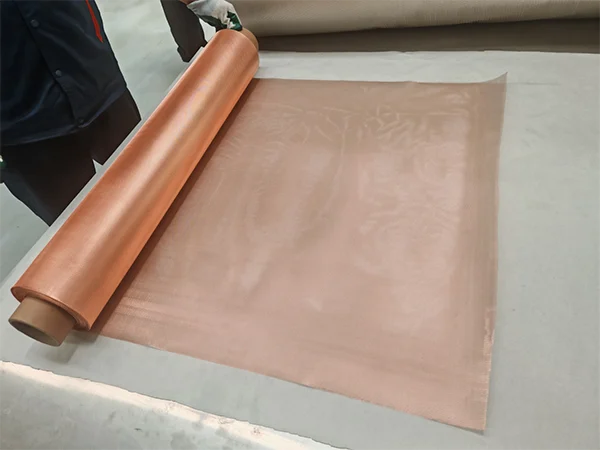

Micro expanded copper mesh is a thin and light metal sheet. It has a single and complete structure that does not fall apart or become entangled. Because of its high malleability, it can be perfectly matched to different parts of the aircraft. It can be embedded in the external laminate of CFRP (carbon fiber reinforced polymer) or in some positions in the surface film, ensuring a smooth surface without affecting the electrical conductivity.

Professional brand specifications reference:

Table 1: Specifications of Micro Expanded Copper Mesh

| Item |

Width |

Areal weight |

LWD±0.0075 |

SWD±0.0075 |

Thickness |

Open Area |

Resistance Ω |

| Inches |

g/㎡ |

Inches |

Inches |

Inches |

% |

Major |

Minor |

| BGCU1 |

31, 36 |

78 |

0.065 |

0.041 |

0.004 |

89 |

35 |

85 |

| BGCU2 |

36 |

107 |

0.109 |

0.073 |

0.005 |

88 |

22 |

67 |

| BGCU3 |

36 |

141 |

0.108 |

0.072 |

0.005 |

84 |

18 |

55 |

| BGCU4 |

31, 36 |

195 |

0.065 |

0.038 |

0.005 |

78 |

12 |

35 |

| BGCU5 |

31, 36 |

420 |

0.095 |

0.037 |

0.013 |

56 |

5 |

18 |

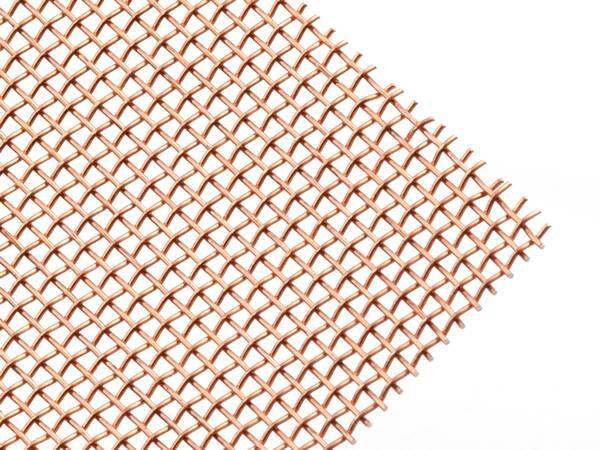

Micro expanded copper mesh product

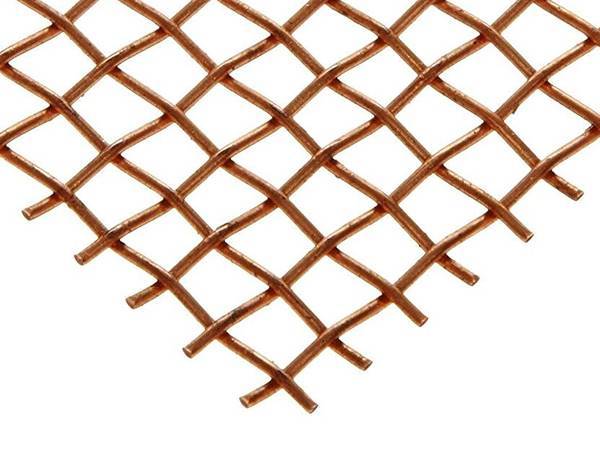

Micro expanded copper mesh aperture

Features

- Outstanding mechanical strength

- High electrical conductivity

- Good lightning protection and electromagnetic interference shielding

- Excellent shielding effect and thermal conductivity

- Overall structure is continuous, not easily broken, and does not hinder conductivity

- Can be rolled flat to make the surface smoother and more even, which is beneficial for bonding installation, as well as for applying additional anti-corrosion or anti-fracture coatings

- Can be flexibly designed according to different applications (including mesh size, stem width, length and width, weight, and porosity)

Applications

Micro expanded copper meshes are required in aircraft fuselage, wings, engine nacelles, flaps, wingtips, and even rotating blades of aircraft.

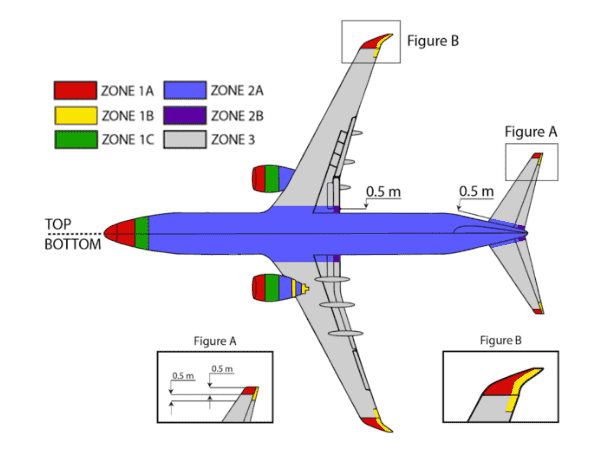

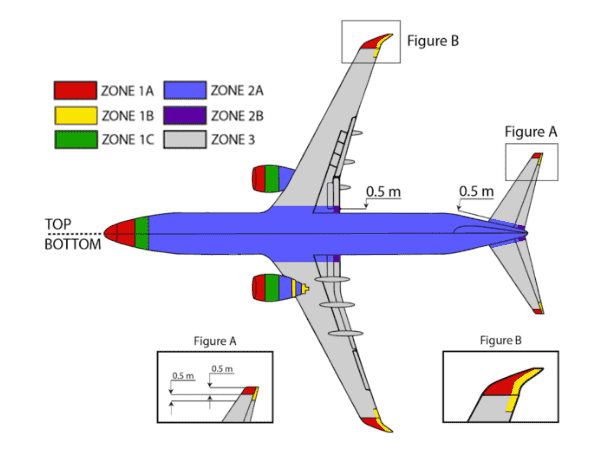

Different micro expanded copper meshes on aircraft

According to SAE ARP 5414, aircraft surfaces can be divided into three zones: Zone 1A, Zone 1B-1C-2A-2B and Zone 3. We recommend using different micro expanded copper meshes for different zones to get the best performance.

Zone 1B and Zone 2B: A double layer of 195 g/m2 or 420 g/m2 copper mesh is required. Because the continuous current will expand the damage area and deepen the damage depth.

- Zone 1A: 195 g/m2 copper mesh is required for protection.

- Zone 1C: 195 g/m2 or 140 g/m2 copper mesh is required.

- Zone 2A: 107 g/m2 copper mesh is required.

- Zone 3: 78 g/m2 copper mesh is required.

Inquiry for Our Product

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

![Knitted Copper Mesh]()

![Woven Copper Mesh]()

![Blackened copper wire mesh image]()

![A roll of brass wire mesh with golden yellow color.]()

![Phosphor copper mesh image]()

![Expanded Copper Mesh]()

![Micro expanded copper mesh]()

![Crimped Copper Wire Mesh]()

![Coarse Copper Mesh]()

![Medium Copper Mesh]()

![Fine Copper Mesh]()

![Copper Shielding Mesh]()

![Cable Shielding Mesh]()

![Faraday Cage]()

![Copper Alloy Fish Cage]()

![Copper Scrubber]()

![Stuf-Fit Copper Mesh]()

![Copper Insect Screen]()

![Copper Fireplace Screen]()

![A piece of copper mesh mask on the gray background.]()

![Fused Glass on Copper Mesh]()

![Copper Mesh Artworks]()